Latest News

Product Spotlight: Fiber Lasers

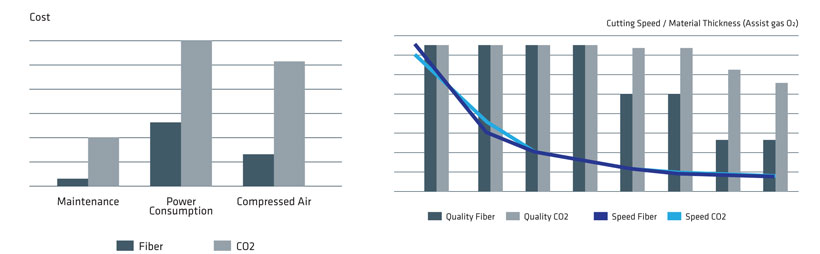

The laser power source of the HDF series is an all-solid-state fiber laser. This technology reduces further the maintenance requirements and offers the lowest possible running cost with a wall-plug efficiency of 30% and without the need of any laser gas. When the application requires a broader spectrum of material types to be cut and the maximum thickness range is limited, the fiber laser is the ideal solution. It will cut faster at lower cost than any CO2 laser at the same laser power.

Maintenance

Maintenance

Fiber lasers are all solid state and have no mechanical parts that could suffer from wear or need little adjustment. The laser source is therefore truly maintenance free and has an expected lifetime of greater than 100,000 hours.

Laser Gas

Laser Gas

Where CO2 lasers are excited by an electrical discharge in a laser gas medium, fiber lasers are powered by diode lasers and require no gas for their operation.

Beam Delivery System

Beam Delivery System

The fiber laser light is brought from the laser source to the cutting head by a flexible glass fiber. There are no mirrors in the beam delivery that require maintenance and adjustment. The light does not travel through air, making a flushing or over-pressurizing with clean air unnecessary.

Reduced Power Consumption

Reduced Power Consumption

Not only will fiber lasers cut faster than CO2 lasers with a similar output power, their wall-plug efficiency of 30% is more than double. There is no standby electrical consumption and also the cooling requirements are only a fraction of that of a CO2 laser.